ROADX 3PL

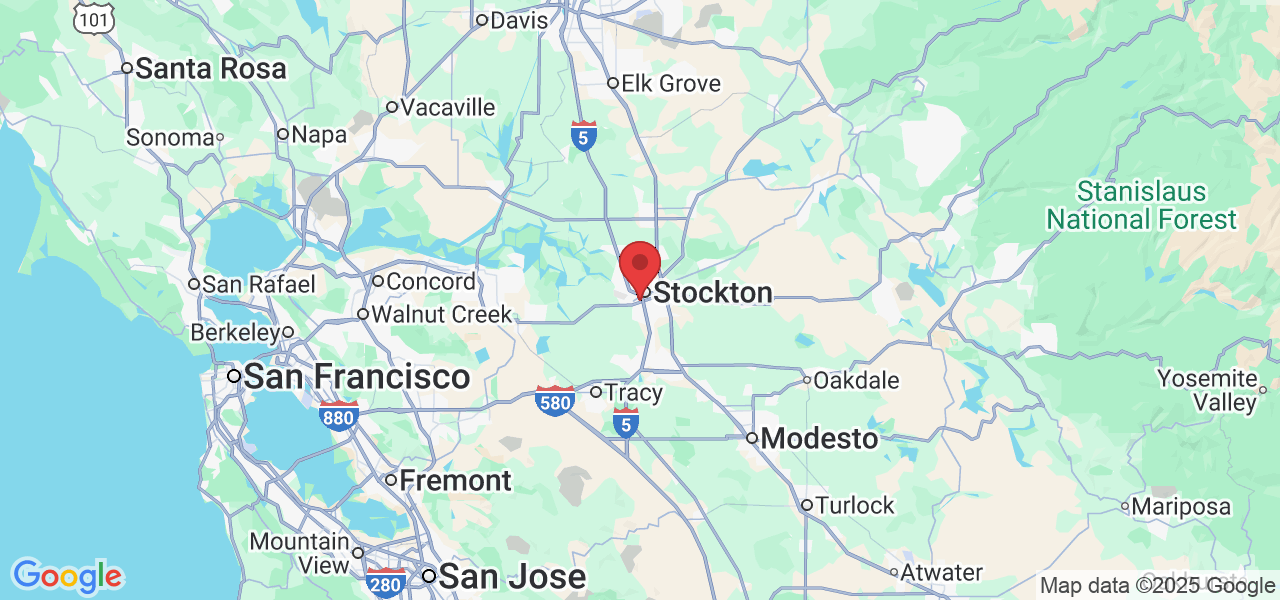

Full-Service Logistics & Warehouse Solutions in Stockton, CA

Distribution • Storage • Transloading • Fulfillment — All Under One Roof.

READY TO GIVE US A TRY?

Improve your supply chain with our strategic warehousing services

Smart Inventory Management powered by real-time tracking, predictive analytics, and demand forecasting for total visibility across your supply chain.

Flexible Storage Options from short-term pallet-in/pallet-out to full-service fulfillment and nationwide distribution.

Optimized Multi-Client Facilities enabling cost efficiency, shared resources, and fast scalability for growing businesses.

Advanced Warehouse Automation leveraging cutting-edge systems for faster order processing, accuracy, and operational speed.

Rapid Cross-Docking Solutions that minimize storage time, accelerate throughput, and improve last-mile delivery performance.

Temperature-Controlled Storage to protect sensitive, perishable, and high-value products in a stable environment.

Scalable On-Demand Warehousing with adjustable space and flexible contracts — perfect for seasonal or overflow inventory.

Seamless Transportation Integration connecting warehousing with freight forwarding, trucking, and port access for a true end-to-end logistics solution.

Prime Location Benefits just minutes from I-5, Highway 99, and the Port of Stockton — providing direct access to Northern and Southern California, Reno, and the entire West Coast distribution corridor.

Modern 3PL Capabilities, Built for Scale

RoadX 3PL delivers flexible storage, real-time visibility, and automation that moves product faster—at lower cost.

Multi-Client Campus Model

Share resources across clients while keeping control and visibility—unlocking flexibility and cost efficiency at scale.

Advanced Inventory Intelligence

Real-time visibility and predictive analytics deliver proactive control of on-hand, turns, and replenishment.

Tailored Storage & Fulfillment

From pallet-in/pallet-out to complex multi-channel distribution—solutions matched to your exact requirements.

Smart Warehouse Automation

Robotics and AI-driven workflows accelerate pick/pack/deploy and reduce labor costs—without sacrificing accuracy.

How Our Warehouse Management Process Works

- Inbound Receipt: We receive products, inspect for quality, and integrate them into our WMS with full visibility.

- Systematic Putaway: We place items in optimal storage zones using data on order velocity and SKU characteristics.

- Inventory Control: Continuous cycle counts and real-time tracking ensure unmatched accuracy.

- Order Processing: Optimized pick paths and intelligent resource allocation speed fulfillment.

- Quality Verification: Multi-point inspections ensure every order is packed with precision before shipping.

- Outbound Coordination: Integrated transportation and distribution for seamless last-mile delivery.

- Performance Monitoring: We track KPIs and drive continuous improvement through analytics and automation.

99.7% of shipments across the U.S. are delivered within two days or less.

Powering Efficiency at Scale

Powering Efficiency at Scale

Core Warehousing Services

Campus-Based Warehousing

Maximize efficiency through multi-client campus environments. Share labor, equipment, and resources while maintaining dedicated service levels—providing scalability and cost advantages impossible in standalone operations.

On-Demand Warehousing

Access flexible warehouse space across the U.S. with short-term agreements. Perfect for seasonal peaks, promotional periods, or market testing without long-term commitments.

Foreign-Trade Zone Services

Defer duties and optimize cash flow through full FTZ operations. Store, manipulate, and distribute imported goods while minimizing landed costs and maintaining compliance.

Inventory Management

Transform inventory control with predictive analytics, automated replenishment, and real-time visibility. Reduce overstock, optimize rotations, and maintain product availability at scale.

Cross-Docking Operations

Accelerate product flow from inbound to outbound. Reduce storage delays, consolidate shipments, and minimize handling—speeding up delivery with maximum efficiency.

Warehouse Automation

Boost productivity with robotics and automated workflows that deliver measurable efficiency and strong ROI across every facility in the RoadX network.

Frequently Asked Questions About Warehousing & 3PL Logistics

What Warehouse Management System does RoadX 3PL use?

RoadX 3PL uses a proprietary Warehouse Management System (WMS) designed for speed, scalability, and full visibility. It integrates with advanced warehouse automation such as robotics, automated sortation, and RFID scanning. Our WMS connects directly to warehouse control systems for equipment like Locus Robotics, goods-to-person systems, and print-and-apply labeling. Clients enjoy 24/7 real-time access to inventory data, order tracking, and custom KPI dashboards through our Visibility Portal. The system integrates seamlessly via API, EDI, and web services with your ERP or OMS for complete supply chain transparency.

How does RoadX ensure warehouse flexibility for seasonal demand?

Our multi-client campus model gives you on-demand scalability across 20+ strategic warehouse hubs. Labor, space, and resources shift instantly between facilities, allowing you to handle seasonal peaks or promotional spikes without long-term commitments. Flexible short-term agreements mean you can ramp up for busy seasons and scale back when demand drops — all with trained warehouse teams and automated systems that keep your costs low and fulfillment times fast.

What makes RoadX warehouse automation different?

We take a data-driven approach to automation. Every solution is custom-engineered after analyzing your SKU velocity, order mix, and storage needs. RoadX 3PL remains technology-agnostic — meaning we deploy the best solutions for you, not what’s easiest for us. From robotic picking and automated storage/retrieval systems (ASRS) to conveyor sortation and voice-directed workflows, we implement technology proven to deliver ROI, labor efficiency, and accuracy.

How fast can RoadX 3PL launch new warehouse operations?

Through our streamlined LaunchFast™ Program, we can deploy fully functional warehouse operations in as little as 60–90 days. Our experienced teams manage every phase: site prep, systems setup, automation integration, and workforce training. We maintain ready-to-activate space within our national network to support urgent requirements and ensure zero downtime transitions for new clients.

Which industries benefit most from RoadX warehousing solutions?

RoadX operates industry-specific warehouses for healthcare, retail, e-commerce, automotive, food & beverage, and technology sectors. Our FDA-registered, AIB-certified, and temperature-controlled environments meet strict quality and compliance standards. Specialized zones manage lot tracking, JIT delivery, and ESD protection for high-tech goods — all staffed by trained, certified warehouse professionals.

How does RoadX 3PL optimize warehouse space utilization?

Our engineering team continuously optimizes layout and storage density using AI-driven slotting, vertical racking, and dynamic reallocation. We analyze SKU velocity, size, and order frequency to design high-efficiency floor plans. Regular data reviews ensure your space adapts to changes in demand, enabling up to 30% higher cubic utilization and reduced handling time.

What warehouse security measures does RoadX maintain?

Security is built into every site: 24/7 surveillance, biometric access controls, alarm systems, and C-TPAT validation. Sensitive inventories are stored within restricted zones protected by reinforced barriers and monitored access. Our Transported Asset Protection Association (TAPA)-certified facilities exceed global security standards, ensuring peace of mind for high-value goods.

How does contract warehousing with RoadX reduce costs?

Contract warehousing turns fixed costs into flexible, scalable expenses. Our shared-resource model lowers labor, equipment, and overhead by pooling across clients — without compromising quality. You pay only for the space and services you need, while our economies of scale deliver enterprise-level efficiency and lower per-unit costs. It’s the smarter path to flexible growth without the capital burden of owning facilities or tech infrastructure.

Innovation

Fresh, creative solutions.

Integrity

Honesty and transparency.

Excellence

Top-notch services.

Copyright 2025. Nilton/ RoadX 3PL Warehouse Service. All Rights Reserved.

Copyrights 202X | Your Brand™ | Terms & Conditions